I finally built myself a workbench to sort out tools and give me a decent platform to wrench on the cub project – as well as other house tasks too. Handy dandy pegboard to mount the tool selection for ease of selection. The basement has become my man-cave! Still a fair bit of organizing yet but it will develop as I work with it.

Oil Drop Man and his Gal

ESSO not only had the tiger symbol but this cute couple each with a quiff shaped head of a golden oil drop.

Looks like they had fun on two wheels also!

“Happy Go Lively”

This company goes back to Rockefeller and his wealth machine Standard Oil (ess oh being the phonetic initials) Now known as Exxon in the US. They worked on future users with Playmobil toys, here a gas station complete with pumps, canopy and vehicles…

I like to look at some older images, and here is a Triumph ready for a top-up.

Perhaps the Oil Drop mans gal is called Ethel.

Car Repair

Motorcycle fiddling gives you confidence for inner engine bay repair. In my endeavor to sync a notchy gear shift an end connector clamp leg snapped off. So ordering a new part, two to be safe, I swapped out both connectors and adjusted them. One slides the great cluster across the neutral — and the other moves the gears into their respective cluster ratio |||

Gertie is back on the road…

Pointless …

I took an hour today to swap out the points ignition setup for a nifty Pazon electronic ignition, a very straight forward operation only needing care in getting the rotor aligned to TDC. Once there the engine is started and timed on the primary side to the correct 38° advance Varoom, the engine roars into a powerful voice. I nip around the block going up and down the gears with intent. The Bonnie got her giddy-up back!

Zion Bound

The sun shone, a blue sky glowed, and the air was perfect. Mid seventies and a light cool breeze off the lake. A jaunt up north to Zion let the wheels spin underneath and the flowering trees waft along the roadside in heady bloom.

After the carb clean running was good however a hiccup began towards the far north of the trip. We swapped out for new plugs at an Autozone which livened things up, evidence of richness on the left cylinder; however towards home loss of power was evident when twisting the throttle at mid rev range. So! A little more tuning is in order! However a good ride out!

Tool o’ the Day

You can take apart an old Raleigh 3 speed with this spanner multi-tool. From the pedals, bottom bracket lock ring, brake cable adjusters to the handlebar stem nut. It came in handy for my Cub fork dust cap. It needed the backbone c-spanner to fit a notch. A clout wi’ the hammer and jobs a good un.

It’s simple, elegant and serves its purpose with no fuss or breakable plastic bits.

Of Air & Fuel

Mix, ignite and bang! Well that’s the simple idea. Getting it to work is more subtle. So I find myself with disassembled carburetors and new seals, gaskets and o-ring as well as a shiny new needle jet in an attempt to smooth up my throttle action. It was lumpy and low on power last weekend.

An intricate little device, but Amals are fairly straight forward and once you’ve taken it apart and put back together knowing what each component does it becomes more approachable.

Spring road

Out for a Sunday ride: a wee bit chilly but with the odd peep of sun to brighten the road up. Spring leaves flushing out overhead and early blooms adorning the shrubberies.

Dean kicks his Bonnie into life. Mine had a rough throttle pick-up which I need to see to. Hacky dorty carbs, points to readjust, or even a little electrical hiccup …

Lake Cycle

A trip to Indiana yesterday to assist a friend of Dean’s with his Honda; it was to be taken for a tire change. Dean built a nice wide ramp for its transport which made getting it into his truck a doddle.

That Honda dealer and garage was in Merriville and was a neat setup with very friendly staff. the new CB1100 was a particularly nice looking moto: classic retro lines of a seventies superbike. They had a wall of historic photographs showing past bikers and their rides, this included a past incarnation in the sixties as a Triumph dealer. The place to go to pick up your Bonneville.

Proud owners lined up ready for a hare up to the Dunes of Michigan.

Don’t Over tighten!

A lesson te ye all! When it comes to aluminium/aluminum alloy parts you need to be carefully not to overstress them when tightening nuts bolts or other fastenings. Use locknuts, thread lock or just gently nip it up and recheck after a ride.

But will I learn? This fork end cap did have a hairline crack in it and I thought I’d be clever and make an end plate to splint it but it still opened up. I was fortunate to find a single replacement cat the swap meet and put that on. Job done. Lesson larned!

As an old mechanic told my friend Dean once “tighten it until your cheeks part!” But, in the case of alloys

All Geared Up

How the Transmission Works.

Taken from a very clear explanation of the workings of the Cubs gearbox from Princeton site which further details student group restoration of the 200cc gem. Larn yersel motorcycle mechanics! It’s basically three shafts, two of which spin on the same center, and a series of fixed or sliding gears that interlock to achieve different drive ratios transmitting power from the engine (via the clutch) to the back wheel. Great stuff!

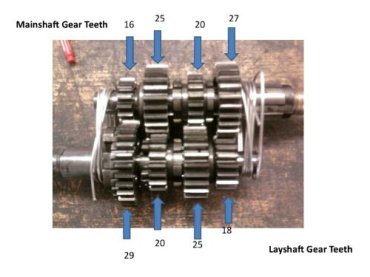

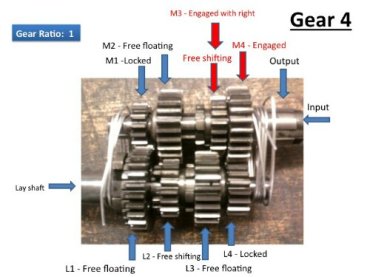

A detailed look into the Triumph TigerCub 4-Gear Transmission System.

The transmission consists of two interlocking shafts with four gears each — the number of teeth on each gear is shown above.

The two shafts are called the mainshaft (shown on the top) and the layshaft (on the bottom). In the TigerCub’s transmission, the mainshaft consists of two parts: the input shaft, which brings power from the engine, and the output shaft, which rides on a bearing concentric to the input shaft but outside of it, and which transmits power to the rear wheel. In the picture above, the input shaft is the smaller, copper-colored cylinder in the upper-right corner, and the output shaft is the larger, silver-colored cylinder to its immediate left.

The input shaft is tied to the first and third gears on the mainshaft (M1 & M3)–that is, it co-rotates with them at the same angular velocity. M2 spins freely unless anchored to the mainshaft by M3, and M4 co-rotates with the output shaft. L2 and L4 co-rotate with the layshaft, and L1 and L3 spin freely unless anchored to the layshaft by L2.

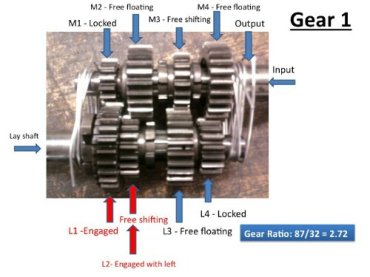

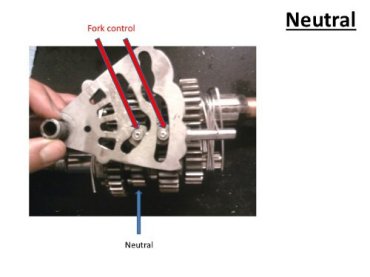

This picture shows the transmission in neutral–that is, the input is disengaged from the output, so the wheel receives no torque despite the engine’s running. M1 and M3 spin with the input shaft, but since M3 is not engaged with either M2 or M4, neither of those two rotates with the mainshaft. M1 and M3 drive L1 and L3, but since L2 is engaged with neither of those gears, they spin freely and the layshaft does not itself rotate. Thus the output via M4 is unaffected by the input.

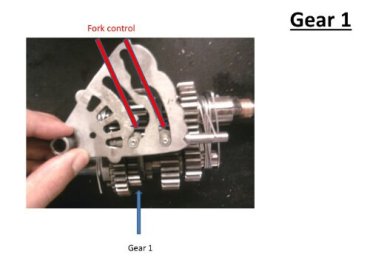

In shifting from neutral to first gear, L2 is moved to the left and engages with L1. This allows M1, co-rotating with the input, to drive the layshaft via L1. The spinning layshaft then drive M4 via L4, giving the gear ratio shown above.

Input => M1 => L1 => Layshaft => L4 => M4 => Output

From first gear, L2 shifts to the right and engages with L3, driven by M3 in the middle position. L3 is smaller than L1, and M3 larger than M1, so a smaller gear ratio results.

Input => M3 => L3 => Layshaft => L4 => M4 => Output

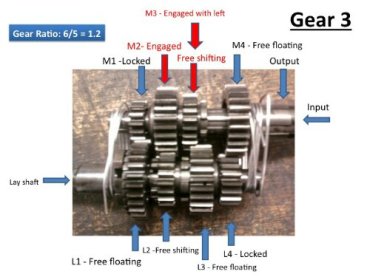

In third gear, L2 shifts back to its middle position, unengaged with either L1 or L3, while M3 shifts to the left and engages with M2. M2, co-rotating with the input, drives L2.

Input => M2 => L2 => Layshaft => L4 => M4 => Output

In fourth gear, L2 remains in the middle, and M3 shifts to the right to engage directly with M4, tying the input immediately to the output. As in neutral, the layshaft is not utilized.

Input => M3 => M4 => Output

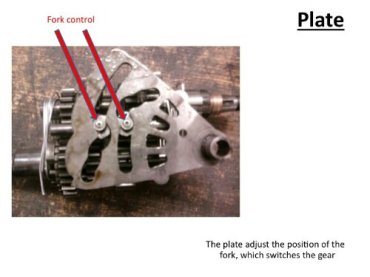

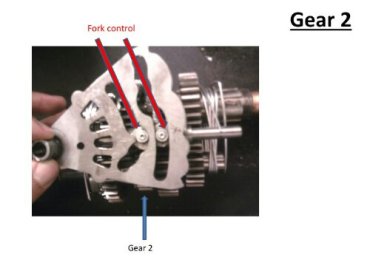

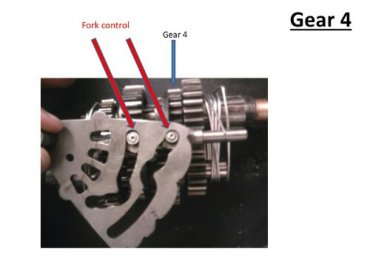

( Based on the position of the two shifting gears (M3 on the mainshaft and L2 on the layshaft), the gear ratio of the transmission is different. The forks control the position of the two shifting gears by sliding them left and right along the shaft. The forks are crescent shaped and fit into slots on the side of the shifting gears so that they are able to move the gears left and right but do not effect the rotation.

Side view of fork engaging gear shoulder.

On top of each of the forks is a roller that fits into a pathway on the shifting plate. As the shifting plate changes positions, the fort-rollers follow the path, thus changing the position of the two forks. It is this motion that allows the transmission to change gears based on the position of the shifting gears.

Back on the Road

A winter project complete! Well it’ll never be complete, ever! But that is the ‘enjoyment’ of owning an old Brit Iron Moto. Took ‘er out for a shake-down and found the new stopper working very well; no fade; a nice feel with my typical couple of fingers feather braking. Still a little electrical gremlin to chase out of the chassis; they like to hibernate in Triumphs stored in dark dry garages! Nevertheless, the bike kicked over easily after sitting up for the winter. Should now get an early start this coming riding season.

New Front

A good couple of hours was spent this afternoon reattaching the front end to my bike. The ‘new’ triple tree was threaded back onto the frames head tube, making sure plenty of grease was slathered into the races. Then the fork stanchions slid back up the fork holders. Wheel mounted and a few more bolts tightened. That makes it sound easy but a few reassembly hurdles had to be surmounted.

Just the brake plumbing to finish, test drive double-check connections then the job’s a gud-un!

You can’t see the wood for the trees

My front end project nears its final lap! My triple tree was returned from the powdercoaters; the grotty item acquired from EBay was bead blasted then given a nice new glossy finish just like it would have looked like from the Midlands factory thirty some years ago. Couple of new bolts to purchase for the lower fork pinch then I can assemble… My easter weekend is fettled for spannerin’ !

Note to self: triple trees for disc brakes are wider than drum brakes…

Now where is that 3/8″ spanner?

I dream of one day having a workshop space with good light, a wall of easily reachable and cell organized tools, a raised work stand, a tough workbench, and a moto sitting aloft nee find tweaked, rebuilt, modified, wrenched or just plain looked-at. One day…

Here’s one of the mechanics stations down at Motoworks. Jealous? Me? Sure!