Assembled! After a few pairs of forks from past rebuilds under my belt; familiarity breeds confidence. These took 15 minutes to put together and are ready to slot into the triple trees atop the frame currently growing into a true chassis.

It’s the front end for forks sake!

Rebuilding the forks this weekend! Tubing, bushes, seals, springs, bolts ‘n’ all: it’s all about oil management under compression. We need to absorb bumps and jostles on the lane so the hand grips aren’t wrenched out of your control. The new stanchions and recently powder coated lower legs will give it a nice appearance. But I’ll be putting bellow’d boots over the shiny bits to stop mud ingress to the all too precious seal.

Framed

Okay! Bolting parts of the frame together. A little bit of a dry-run a some new nuts and washers are required. But taking shape nonetheless. A lot more straight forward than the Bonnie. Also a better workshop and tool setup helps too!

The rear sub frame bolts on at the swingarm spindle bolts and the upper frame seat/tank junction. Lower footpeg and side stand brackets attach here too. The swingarm is temporarily suspended. Measuring for a new set of stainless nuts bolts and washers. All Whitworth thread too.

Any color as long as it’s Black

Frame and fork components were returned today in splendid gloss black powder coated finish. All slick and span and ready for chassis assembly. The work was carried out very capably by JTS Coatings & Cycles in Lakemoor IL.

Charley the Quality Control Cat looks on approvingly. He doesn’t miss a trick!

You say tires I say tyres…

The original tire was a heated steel hoop quench-shrunk onto the wooden wheel. The anglicized tyre was a 20thC spelling only used in Britain. Tire is the standard spelling. Scotsman John Dunlop invented the rubber pneumatic tire, further developed with galvanizing by Charles Goodyear. Now my Cub wheels are shod with lightly knobbled trials boots. Something complete for the project!

Bud

I picked up my cylinder head and barrel today from The Machine Shop, a little hidden gem in Rogers Park where Bud Clements works his time honored magic on engine parts old, new, common and esoteric. He rebored the cylinder to receive the new 60 over piston and cleaned, set new guides, and lapped seats for a pair of valves too. He knows his stuff down to the micron.

The great convergence is upon us!

Rollin’, rollin’, Rollin’.

Dial ’em up

Amal

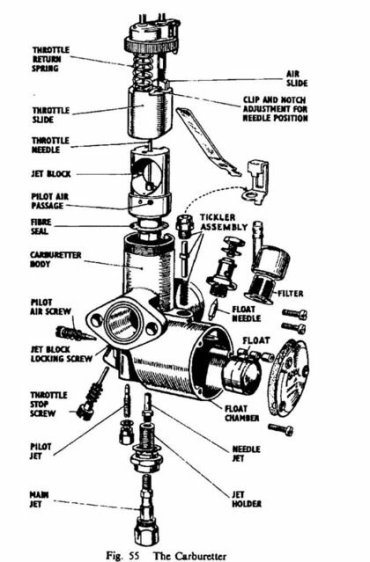

A quick strip of an Amal Monobloc carburetor obtained from eBay reveals a very serviceable item.

A thorough cleaning of parts, new seal kit, needle, springs & jet, and the all important petrol/air mixer will be ready to eventually mount at a later date.

A nice exploded workshop manual illustration will ensure all parts go back where they belong…

Note to self: Amal 376/314, 15/16in choke, 140 main jet, 15 pilot jet, 0.106 needle jet, needle pos’n 3, needle type C, slide 3.5

Amal 375/44 100 main jet, 25 pilot jet, 3.5 cutaway, needle jet 0.11 position 3

Boxed and ready to go!

Sprockets

A new front sprocket arrived in the mail yesterday. Fourteen teeth. Nice long unworn teeth that haven’t been chomping on a chain for miles and miles and miles.

The original setup is an eighteen tooth front sprocket and forty eight tooth rear wheel one. That gives a ratio from the gearbox of 2.66:1. With the 14 front and a big sixty tooth one that will give me a ratio of 4.30:1. Nearly a 60% increase. A good trials gearing!

Dieter says: “You are beautiful and angular.”

Round and round she goes…

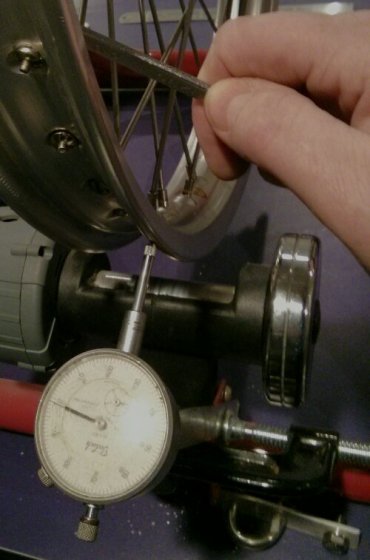

After yesterday’s reuse special here’s one for adaptation. My wheel building exploits needs the next step of truing my new front wheel. I slotted the axle into my bicycle exercise roller. It fitted perfectly and spun freely. All I need to do is find the rims new center alignment and affix some nearby reference pins. Then spun, tweak, spin, twerk, spin, twunk. Repeat. Job’s a good un!

Toolkit

Any self respecting vintage Triumph owner never leaves home without one! Here’s a near original set in aged patina ready to be rolled up, packed in the toolbox and taken on the road. Spanners? Check; Whitworth both open-ended and closed. Spark Plug wrench? Check. Tire irons? Some call ’em spoons, others levers but yep, check! Tappet spanner and feeler gauges? Check; tickety-tackety goes the engine in purring state! Spoke wrench? Check. Can’t be having wobbly wheels after the bumpy cobbles of Dent or the rutted tracks of the New Forest! Air gauge? Check! Pump is on the frame too lest a flat be had! Puncture kit? Check; complete with crayon, glue and vulcanized rubber patch. Grease gun? Grease gun? Yup, grease gun! Check! A small travel sized one should do, gotta keep ’em wheels a-rollin’! And finally screwdriver and pliers? Check, check. They’ll come in handy for something I’m sure…

What about electrics? Lucas? Uhuh! Well, three Hail Mary’s and a How’s your Father should do for that – good luck on that one old chap.

(This kit is currently available on EBay for $200.)

Laced

Forty spokes, forty nipples (yes the wee things that screw onto the spoke providing tension), an alloy rim and a freshly axle’d hub. I have good photos of the left and right side lacing patterns too.

One side done – second effort after not getting the right cross pattern. When turned over it starts to untangle like a wiry spider…

Deliberate care with getting the correct length and inside and outside line set. On the brake side each repeats every fourth hole, with the dimple aimed appropriately, and cross spokes back six holes.

Then on the other side each also every fourth but the cross spokes back ten holes…

Nip the spokes hand tight and basic stability is attained.

Now to True…. Removing hop and wobble!

Lacing

Nope! Not for a boot; nor an antimacassar doily neither: but the front wheel. Getting things sorted and ready to build the front wheel for the Cub. A 21″ alloy hoop, to match the rear 18″ one and forty new Buchanan spokes.

There are four different spokes for inner and outer hub rim as well as left and right side.

When you look at the typical pattern it has a geometrical elegance to it. A ferris dance of tensions on the ‘cycles primary component of conveyance. The wire spoked wheel was invented by Yorkshireman Sir George Cayley (1773-1857) who was also the father if aerodynamics. Understanding the principles of flight a century before the Wright Brothers. The optimism and supporting scientific and engineering progress of the times were truly present in “Eeh bar gum! Ar George” .